Zero turn mowers are efficient machines designed to make lawn maintenance easier and quicker. They’re known for their speed, agility, and ability to navigate around obstacles with precision. Like any other gasoline-powered equipment, proper maintenance is essential to ensure they operate smoothly and efficiently. One critical aspect of maintenance is knowing how to drain gas from a zero turn mower. Whether it’s for winter storage or regular maintenance, properly draining the fuel can prevent starting issues and ensure your mower performs optimally when you need it.

Understanding Your Zero Turn Mower

Before diving into the process of draining gas from your zero turn mower, it’s important to understand its components and how they work together. Zero turn mowers are characterized by their ability to turn on the spot, thanks to hydraulic speed control of each drive wheel. This allows for greater maneuverability and efficiency when cutting grass, especially in large, open areas.

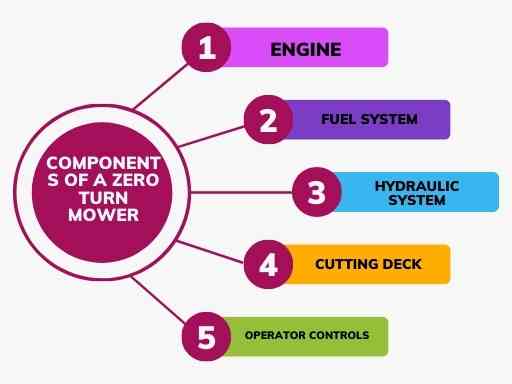

Components of a Zero Turn Mower

To effectively drain gas from your zero turn mower, you need to familiarize yourself with its main components. Each component plays a vital role in the mower’s operation and maintenance:

Engine

The engine is the powerhouse of the zero turn mower. Most zero turn mowers are equipped with gasoline engines, although some high-performance or commercial models might use diesel engines. The engine’s primary function is to provide power to the cutting blades and drive the mower forward. Key aspects of the engine include:

- Spark Plug: Ignites the fuel mixture in the engine’s cylinder.

- Carburetor or Fuel Injection System: Mixes fuel with air to create a combustible mixture.

- Air Filter: Ensures that the air entering the engine is free of dust and debris.

Understanding the engine’s fuel requirements and maintenance needs is crucial for optimal performance and longevity.

Fuel System

The fuel system is integral to the mower’s operation, as it stores and delivers gasoline to the engine. It consists of several components that need regular maintenance:

- Fuel Tank: Stores the gasoline. Located under the seat or in the rear of the mower, it can usually be accessed by lifting the seat or a cover.

- Fuel Lines: Transport fuel from the tank to the engine. These lines need to be inspected for cracks or leaks regularly.

- Fuel Filter: Removes impurities from the gasoline before it reaches the engine. The filter should be replaced periodically to prevent clogs.

- Carburetor or Fuel Injection System: Mixes fuel with air in the correct ratio for combustion. Keeping this component clean ensures efficient fuel usage.

Proper care of the fuel system, including draining old gas, helps maintain engine performance and prevents common issues like clogging and poor combustion.

Hydraulic System

Zero turn mowers are renowned for their precise control and maneuverability, made possible by the hydraulic system. This system includes:

- Hydraulic Pumps and Motors: Control the speed and direction of each drive wheel independently.

- Hydraulic Fluid: Essential for the smooth operation of the hydraulic components. Regularly check and maintain fluid levels to prevent overheating and ensure efficient operation.

The hydraulic system’s maintenance, while not directly related to the fuel, is crucial for the overall performance of the mower.

Cutting Deck

The cutting deck houses the blades that perform the actual cutting of the grass. The deck size can vary, typically ranging from 42 inches to 72 inches or more. Key components of the cutting deck include:

- Blades: Sharp blades ensure a clean cut and reduce stress on the engine.

- Spindles and Pulleys: Transfer power from the engine to the blades.

- Deck Height Adjusters: Allow you to set the cutting height according to your lawn’s needs.

Regularly clean and inspect the cutting deck to prevent buildup of grass clippings and debris, which can affect performance and lead to corrosion.

Operator Controls

Operator controls are essential for the safe and efficient operation of the mower. These controls typically include:

- Throttle Control: Regulates engine speed.

- Blade Engagement Lever or Switch: Engages the blades to start cutting.

- Steering Levers: Control the direction and speed of the mower. Zero turn mowers use independent lever control for each wheel, allowing for precise turns and maneuvering.

Understanding and maintaining these controls ensures that the mower responds accurately to the operator’s inputs, enhancing safety and efficiency.

Draining Gas from a Zero Turn Mower

Draining gas from your zero turn mower is a straightforward process, but it requires attention to detail to avoid spills and ensure safety. Here’s a step-by-step guide:

Preparation

- Safety First: Ensure the mower is on a flat, stable surface. Turn off the engine and remove the key. Allow the engine to cool if it has been running.

- Tools Needed: Gather necessary tools such as a siphon pump, a gas can, and protective gloves and eyewear.

Accessing the Fuel System

- Locate the Fuel Tank: This is usually under the seat or a protective cover. Remove any covers to access the tank.

- Check the Fuel Level: If the tank is full, you might want to run the engine for a while to lower the fuel level before draining.

Draining the Gas

- Using a Siphon Pump: Insert one end of the siphon pump into the fuel tank and the other end into a gas can. Follow the pump instructions to start siphoning the fuel.

- Alternative Method: If a siphon pump is not available, you might be able to remove the fuel line from the carburetor or fuel injection system and let the fuel drain into a gas can. Be prepared for fuel to flow quickly once the line is detached.

Disposing of the Gasoline

- Proper Disposal: Old gasoline should be disposed of properly according to local regulations. Do not pour it down drains or on the ground.

- Storage for Future Use: If the gas is still good, store it in a properly labeled, airtight gas can away from heat sources and direct sunlight.

Cleaning and Maintenance

- Inspect the Fuel Tank: Check for debris or water at the bottom of the tank and clean if necessary.

- Fuel Lines and Filter: Inspect the fuel lines for cracks or leaks and replace the fuel filter if it appears dirty or clogged.

Why Drain Gas from Your Zero Turn Mower?

Gasoline is a vital component for the operation of zero turn mowers, but it can degrade over time, leading to a host of issues. Draining the fuel from your zero turn mower is an essential maintenance task that should not be overlooked. Here are several key reasons why you should make it a routine part of your mower’s upkeep:

Prevent Starting Problems

Old gasoline can cause varnish and gum buildup in the fuel system. As gasoline ages, it can oxidize and break down, forming sticky residues that can clog fuel lines and carburetors. This buildup can restrict the flow of fuel to the engine, making it difficult to start your mower. Symptoms of fuel system blockages include:

- Hard Starting: The engine cranks but does not start easily.

- Rough Idling: The engine runs unevenly or stalls at idle.

- Inconsistent Performance: The mower may run well at times but then lose power or stall.

Draining old gasoline and replacing it with fresh fuel helps to prevent these problems, ensuring that your mower starts easily and runs smoothly.

Avoid Engine Damage

Stale fuel can lead to engine deposits and corrosion, which can significantly affect your mower’s performance and longevity. As gasoline degrades, it loses its combustive properties and can form acids that are harmful to the engine’s internal components. Potential damage includes:

- Deposits: Gum and varnish deposits can form on valves, pistons, and other engine parts, reducing efficiency and power.

- Corrosion: Moisture in stale gasoline can lead to rust and corrosion inside the fuel system and engine, potentially causing irreversible damage.

- Fuel Injector Issues: In fuel-injected mowers, degraded gasoline can clog injectors, leading to poor spray patterns and uneven fuel distribution.

By draining the fuel system before storing your mower, you can avoid these issues and protect your engine from unnecessary wear and tear.

Prepare for Storage

If you’re storing your mower for an extended period, such as over the winter months, draining the fuel is crucial. Gasoline left in the tank can go bad, leading to starting problems and engine damage when you try to use the mower again. Proper storage preparation includes:

- Empty Fuel Tank: Draining the tank prevents the gasoline from degrading and forming gum deposits.

- Prevent Moisture Build-Up: An empty tank reduces the risk of moisture condensation, which can cause rust and corrosion.

- Fuel Stabilizer: If you choose not to drain the tank completely, adding a fuel stabilizer can help keep the gasoline fresh for up to a year.

Properly preparing your mower for storage ensures that it will be ready to use when you need it next season, without the hassle of dealing with stale fuel-related problems.

Routine Maintenance

Regularly changing the fuel in your zero turn mower is part of good maintenance practice. Fresh fuel helps to maintain optimal engine performance and efficiency. Benefits of routine fuel maintenance include:

- Consistent Performance: Fresh gasoline ensures that your mower runs smoothly, providing consistent power and performance.

- Longer Engine Life: Regular maintenance, including fuel management, helps to extend the life of your mower by reducing the risk of engine damage.

- Efficiency: Fresh fuel burns more efficiently, improving fuel economy and reducing emissions.

By making fuel management a regular part of your maintenance routine, you can enjoy a mower that starts easily, runs efficiently, and lasts longer.

Summary

Draining gas from your zero turn mower is an essential maintenance task that helps prevent starting problems, avoid engine damage, prepare the mower for storage, and ensure consistent performance through routine maintenance. By understanding the importance of fuel management and following proper procedures, you can maintain the performance and longevity of your zero turn mower, ensuring it remains a reliable tool for lawn care for many seasons to come. Regularly attending to the fuel system not only protects the engine but also contributes to the overall health and appearance of your lawn by ensuring that your mower performs at its best.

Steps to Drain Gas from a Zero Turn Mower

Draining gas from a zero turn mower is a straightforward process, but it requires careful attention to prevent spills and ensure safety. Here’s a detailed guide on how to do it effectively:

Gather Your Tools and Materials

Before you start, make sure you have all the necessary tools and materials at hand. Proper preparation ensures the process goes smoothly and safely.

- Safety Glasses and Gloves: Protect your eyes and hands from gasoline, which can be harmful upon contact.

- Fuel Container: A suitable, approved container to safely store the drained gasoline. It should be designed for fuel storage and be equipped with a secure cap.

- Socket or Wrench: These tools are necessary to remove the fuel tank cap or disconnect the fuel line if required. The exact size may vary depending on your mower model.

- Funnel: Helps to pour the gasoline into the container without spilling.

- Rags or Paper Towels: Useful for cleaning up any accidental spills or drips.

Safety Precautions

Safety should be your top priority when handling gasoline. Follow these precautions to minimize risk:

- Work in a Well-Ventilated Area: Perform the draining process outdoors or in a well-ventilated area to avoid inhaling gasoline fumes. Gasoline vapors are not only harmful but also highly flammable.

- Avoid Open Flames or Sparks: Gasoline is extremely flammable. Ensure you keep away from cigarettes, sparks, or open flames during the entire process. This includes turning off any nearby ignition sources such as water heaters or other appliances with pilot lights.

Locate the Fuel Tank

The location of the fuel tank can vary depending on your zero turn mower model. Typically, it can be found in the following places:

- Under the Seat: Many zero turn mowers have the fuel tank located under the seat for easy access. Lift the seat to expose the fuel tank.

- Consult the Operator’s Manual: If you’re unsure where the fuel tank is located, refer to the operator’s manual for your specific mower model. The manual will provide detailed information about the fuel system and its components.

Turn Off the Engine and Let it Cool

Before you begin draining the fuel, ensure the mower’s engine is turned off and has had time to cool down. Working with a hot engine can be dangerous as it increases the risk of accidental ignition of gasoline vapors.

Remove the Fuel Tank Cap

If your mower has a removable fuel tank cap, carefully unscrew it to access the fuel tank. Removing the cap allows air to enter the tank, making it easier to drain the gasoline. If your mower does not have a removable cap, proceed to the next step.

Disconnect the Fuel Line (if applicable)

Some zero turn mowers may require you to disconnect the fuel line to drain the gasoline. Here’s how to do it:

- Identify the Fuel Line: Locate the fuel line running from the fuel tank to the engine. It is usually a rubber or plastic hose.

- Use a Socket or Wrench: Carefully loosen and disconnect the fuel line from the fuel tank or fuel filter using a socket or wrench. Be prepared for gasoline to flow out once the line is disconnected. Have your fuel container and funnel ready to catch the fuel.

Drain the Gasoline

There are two primary methods to drain gasoline from the fuel tank: direct draining and siphoning.

- Direct Draining: Tilt the mower carefully to pour the gasoline directly from the fuel tank into your fuel container. Use the funnel to minimize spills. This method is straightforward but may require physical strength and precision to handle the mower safely.

- Siphoning: Alternatively, use a siphoning hose or pump to extract the gasoline from the fuel tank into your container. Insert one end of the siphon into the fuel tank and the other end into the fuel container. Follow the instructions for the siphon pump to start the flow of gasoline.

Dispose of the Gasoline Properly

Once you’ve drained the gasoline, it’s important to dispose of it correctly:

- Seal the Container: Ensure the container is tightly sealed and labeled as “Used Gasoline” to avoid confusion.

- Take it to a Disposal Facility: Do not pour old gasoline down the drain, on the ground, or in the trash. Take it to an appropriate disposal facility or recycling center that accepts old gasoline and other hazardous materials. Many local waste management facilities offer disposal services for hazardous household waste.

Inspect and Clean

After draining the gasoline, take the opportunity to inspect and clean the fuel system:

- Inspect the Fuel Tank: Check the fuel tank for any debris or sediment that may have accumulated. Use a clean cloth or rag to wipe out the tank if necessary.

- Replace Fuel Filter (if needed): Depending on your mower’s maintenance schedule, consider replacing the fuel filter. A clean fuel filter ensures that only clean gasoline reaches the engine, improving performance and longevity.

Refill with Fresh Gasoline

Before using your zero turn mower again, refill the fuel tank with fresh, high-quality gasoline. This step is crucial for optimal engine performance and reliability:

- Use Fresh Gasoline: Always use fresh gasoline and, if possible, include a fuel stabilizer to keep the gasoline fresh longer.

- Check for Leaks: After refilling, check the fuel system for any leaks, especially around the fuel line connections and the fuel tank cap. Address any issues immediately to prevent fuel leaks.

Maintaining your zero turn mower involves regular care and attention, including knowing how to properly drain gasoline when needed. By following these steps, you can ensure your mower operates efficiently and reliably throughout its lifespan. Proper maintenance not only enhances performance but also prolongs the mower’s overall durability. Always consult your mower’s operator manual for specific instructions and safety guidelines tailored to your model. Regularly draining old gasoline and replacing it with fresh fuel is a simple yet crucial step in keeping your zero turn mower running smoothly and efficiently.

Additional Maintenance Tips for Your Zero Turn Mower

Maintaining a zero turn mower goes beyond just draining gas. Proper maintenance ensures your mower performs efficiently, has a longer lifespan, and provides a clean, even cut. Here are some additional maintenance tips to keep your mower in top condition:

Oil Change

Just like a car, a zero turn mower requires regular oil changes to ensure smooth operation and longevity of the engine. Follow the manufacturer’s guidelines for oil type and change intervals. Typically, oil should be changed at least once a season or after every 50 hours of use.

Steps for Changing Oil:

- Locate the Oil Drain Plug: The oil drain plug is typically found underneath the mower. Consult your operator’s manual if you’re unsure of its location.

- Drain the Old Oil: Place an oil pan underneath the drain plug. Carefully remove the plug and allow the old oil to drain completely into the pan.

- Replace the Drain Plug: Once the oil has drained, replace the drain plug securely.

- Refill with Fresh Oil: Refer to the manufacturer’s recommended oil type and capacity. Use a funnel to refill the engine with fresh oil. Check the oil level with the dipstick to ensure it’s filled to the correct level.

Air Filter Maintenance

The air filter prevents dirt and debris from entering the engine, ensuring clean air intake. A dirty air filter can reduce engine performance and efficiency, leading to increased fuel consumption and potential engine damage.

Cleaning the Air Filter:

- Remove the Air Filter Cover: Locate the air filter cover and remove it.

- Inspect the Filter: Check the filter for dirt and debris. If it’s slightly dirty, you can clean it. If it’s heavily soiled, it’s best to replace it.

- Clean the Filter: Gently tap the filter to remove loose dust. For more thorough cleaning, use compressed air to blow out debris from the filter.

- Replace if Necessary: If the filter is very dirty or damaged, replace it with a new one according to the manufacturer’s recommendations.

Blade Maintenance

Sharp blades are crucial for a clean and even cut. Dull blades can tear grass rather than cut it cleanly, leading to a ragged appearance and potentially stressing the grass.

Blade Sharpening:

- Remove the Blades: Ensure the engine is off and the spark plug is disconnected for safety. Use a wrench to remove the blades from the mower deck.

- Sharpen the Blades: Use a grinder or file to sharpen the blades to a fine edge. Be careful to maintain the blade’s original angle and ensure both sides are equally sharpened.

- Check for Balance: To ensure the blades are balanced, hang the blade on a nail. If one side dips, grind a bit more from the heavier end until it balances evenly.

- Reinstall the Blades: Once sharpened and balanced, reinstall the blades securely onto the mower.

Blade Replacement: If blades are severely damaged or worn, consider replacing them with new ones for optimal cutting performance. Always use blades recommended by the manufacturer for your specific mower model.

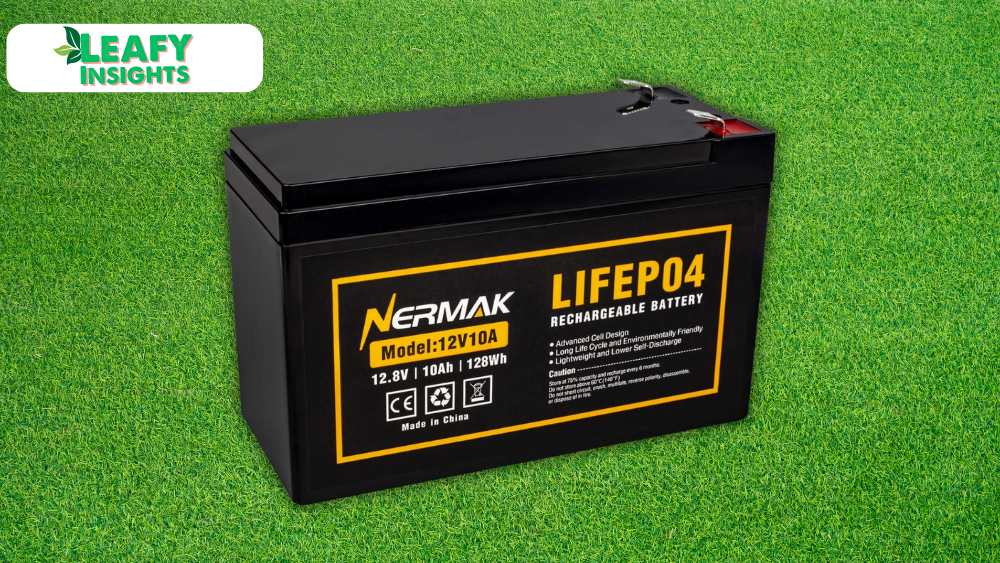

Battery Care

Zero turn mowers often have a battery for starting, especially if equipped with electric start features. Proper battery maintenance ensures reliable starting and extends battery life.

Battery Charging:

- Use a Battery Maintainer: During periods of storage or infrequent use, keep the battery charged using a battery maintainer or trickle charger. This prevents the battery from discharging completely and extends its lifespan.

- Regular Charging: If the mower is used regularly, charge the battery as per the manufacturer’s instructions to maintain optimal performance.

Cleaning Terminals:

- Inspect and Clean: Periodically inspect the battery terminals for corrosion. Clean the terminals with a wire brush and apply a thin layer of petroleum jelly to prevent future corrosion.

- Secure Connections: Ensure the battery connections are tight and secure to maintain proper electrical flow.

Tire Maintenance

Maintaining proper tire pressure and checking for wear ensures the mower handles well and provides a smooth ride, which is essential for both performance and safety.

Tire Inflation:

- Check Tire Pressure: Regularly check the tire pressure with a tire gauge. Inflate the tires to the manufacturer’s recommended pressure levels. Properly inflated tires ensure even cutting and reduce wear on the mower.

Inspect Tread:

- Check for Wear or Damage: Look for signs of wear, cracks, or damage in the tire tread. Worn or damaged tires can affect traction and maneuverability.

- Replace Tires if Necessary: If tires are significantly worn or damaged, replace them to ensure optimal performance and safety. Use tires that meet the specifications provided by the mower’s manufacturer.

Additional Tips

- Spark Plug Maintenance: Check the spark plug regularly and replace it if it shows signs of wear or damage. A clean spark plug ensures efficient engine ignition.

- Hydraulic Fluid Check: For mowers with hydraulic systems, regularly check the hydraulic fluid level and top it up if necessary. Use the fluid type recommended by the manufacturer.

- Belt Inspection: Inspect the mower’s belts for signs of wear, cracks, or fraying. Replace worn belts to maintain the efficiency of the mower’s drive and cutting systems.

- Clean the Mower Deck: After each use, clean the mower deck to remove grass clippings and debris. This prevents build-up that can lead to corrosion and affect cutting performance.

- Lubricate Moving Parts: Regularly lubricate the mower’s moving parts, such as wheel bearings and pivot points, to reduce friction and wear.

By following these maintenance tips, you can ensure your zero turn mower remains in top condition, providing reliable performance and a pristine lawn. Regular maintenance not only enhances the mower’s efficiency but also extends its lifespan, ensuring you get the best value from your investment. Always refer to your mower’s operator manual for specific maintenance schedules and procedures tailored to your model.

Winterizing Your Zero Turn Mower

Properly winterizing your zero turn mower is crucial to ensure it starts easily and runs smoothly when the mowing season returns. Beyond draining the gas, follow these detailed steps to prepare your mower for the winter months:

Stabilize Fuel

One of the most important steps in winterizing your mower is to stabilize the fuel. Even if you drain most of the gasoline, some residue can remain in the system.

- Add a Fuel Stabilizer: Pour the recommended amount of fuel stabilizer into the fuel tank. Stabilizers prevent the gasoline from breaking down and forming gum and varnish deposits that can clog the fuel system.

- Run the Engine: Start the mower and let it run for a few minutes. This ensures the stabilized fuel circulates through the entire fuel system, including the carburetor and fuel lines. This step helps protect these components from corrosion and clogging during storage.

Change Oil and Filter

Changing the oil and oil filter is another essential step in winterizing your mower. Fresh oil helps minimize internal corrosion and wear during the storage period.

- Drain the Old Oil: Run the engine for a few minutes to warm up the oil, making it easier to drain. Turn off the engine and locate the oil drain plug. Place an oil pan underneath, remove the drain plug, and allow the old oil to drain completely.

- Replace the Oil Filter: Remove the old oil filter and replace it with a new one. Apply a thin layer of oil to the gasket of the new filter before installing it to ensure a proper seal.

- Refill with Fresh Oil: Replace the drain plug and refill the engine with fresh oil according to the manufacturer’s specifications. Check the oil level with the dipstick to ensure it’s filled to the correct level.

Clean the Mower

Thoroughly cleaning your mower before storing it for the winter helps prevent corrosion and deters pests.

- Remove Grass Clippings and Debris: Use a brush or compressed air to remove grass clippings, dirt, and debris from the mower deck, blades, and undercarriage. These materials can hold moisture and cause rust and corrosion over time.

- Wash the Exterior: Wipe down the exterior of the mower with a damp cloth. Avoid using excessive water, especially near the engine and electrical components.

- Dry Completely: Ensure the mower is completely dry before storing it to prevent moisture-related issues.

Store Indoors (if possible)

Storing your mower indoors in a dry, protected area significantly prolongs its lifespan and maintains its condition.

- Choose a Storage Location: If possible, store the mower in a garage, shed, or any covered area that provides protection from the elements. Exposure to rain, snow, and freezing temperatures can cause damage to various components.

- Cover the Mower: If indoor storage is not available, use a high-quality, weather-resistant cover to protect the mower from dust, moisture, and other environmental factors.

- Elevate the Mower: If storing outdoors, consider elevating the mower on blocks to keep it off the ground. This can help prevent moisture from seeping into the tires and other parts.

By following these steps, you can effectively winterize your zero turn mower, ensuring it remains in optimal condition and is ready to perform when the next mowing season begins. Proper winterization not only prevents potential damage but also extends the lifespan of your mower, making your investment last longer.

Common Problems and Troubleshooting for Zero Turn Mowers

Even with regular maintenance, issues can arise with zero turn mowers. Understanding common problems and how to troubleshoot them can help you quickly get back to maintaining your lawn. Here are some typical issues and their solutions:

Engine Won’t Start

One of the most frustrating issues is when the mower’s engine refuses to start. This can be due to several reasons, and systematically checking each potential cause can help identify and resolve the problem.

Troubleshooting Steps:

- Check Fuel Level: Ensure there is enough gasoline in the tank. Sometimes, the simplest solution is the correct one.

- Inspect Spark Plug: Remove the spark plug and check its condition. Clean any deposits from the plug or replace it if it’s worn out. Ensure the spark plug wire is securely connected.

- Battery Charge: Check the battery voltage with a multimeter. If the battery is low or dead, recharge it or replace it if necessary. Ensure the battery terminals are clean and tightly connected.

- Safety Switches: Ensure all safety switches are engaged properly. These include the seat switch, blade engagement switch, and parking brake switch. If any of these switches are not engaged, the engine may not start.

- Fuel Quality: If the fuel is old, drain it and replace it with fresh gasoline. Old fuel can lead to starting problems due to its degraded quality.

Uneven Cutting

Uneven cutting can make your lawn look unattractive and may be a sign that something is wrong with your mower’s cutting system.

Troubleshooting Steps:

- Check Blade Sharpness: Dull blades can tear grass instead of cutting it cleanly, leading to an uneven cut. Remove the blades and sharpen them if necessary.

- Blade Balance: Unbalanced blades can cause vibration and uneven cuts. After sharpening, check the balance of the blades by hanging them on a nail or using a blade balancer. If one side dips, grind a bit more from the heavier end until balanced.

- Level the Deck: A misaligned deck can cause uneven cutting. Use a level to check the mower deck. Adjust the deck height according to the manufacturer’s instructions to ensure it is even on all sides.

- Check Tire Pressure: Unequal tire pressure can cause the mower deck to sit unevenly. Ensure all tires are inflated to the recommended pressure.

Loss of Power

If your mower is losing power, it can make mowing difficult and inefficient. This issue can be caused by a variety of factors.

Troubleshooting Steps:

- Air Filter: A clogged air filter restricts airflow to the engine, causing a loss of power. Remove the air filter and clean it if it’s dirty, or replace it if necessary.

- Fuel Quality and Flow: Check the fuel for contamination or degradation. Ensure the fuel lines are clear and fuel is reaching the engine. Replace old or contaminated fuel with fresh gasoline.

- Inspect Spark Plugs: Fouled or damaged spark plugs can cause power loss. Remove the spark plugs, clean any deposits, and check the gap. Replace them if they are worn out or damaged.

- Check for Blockages: Ensure there are no obstructions in the mower deck or exhaust system that could restrict engine performance.

Hydraulic Issues

Hydraulic problems can affect the maneuverability and performance of zero turn mowers. These issues can be due to fluid leaks, low fluid levels, or damaged hydraulic components.

Troubleshooting Steps:

- Hydraulic Fluid Level: Check the hydraulic fluid reservoir and ensure it is filled to the recommended level. Add fluid if necessary, using the type specified by the manufacturer.

- Inspect for Leaks: Look for signs of hydraulic fluid leaks around hoses, fittings, and seals. Repair or replace any damaged components to prevent further fluid loss.

- Check Hoses for Damage: Inspect hydraulic hoses for cracks, wear, or other damage. Replace any compromised hoses to ensure proper fluid flow.

- Hydraulic Pump and Motor: If hydraulic issues persist, there could be a problem with the pump or motor. These components might require professional inspection and repair.

Summary

Maintaining your zero turn mower involves regular checks and addressing common problems promptly. By understanding these common issues and following the troubleshooting steps, you can ensure your mower operates efficiently and reliably. Proper maintenance not only helps in avoiding these problems but also extends the lifespan of your mower, ensuring a well-kept lawn throughout the mowing season.

Choosing the Right Zero Turn Mower

Selecting the right zero turn mower involves considering several factors, including your lawn size, terrain, and the specific features that will best suit your needs. Here are the key elements to consider when choosing a zero turn mower:

Deck Size

The deck size of a zero turn mower determines how much grass it can cut in a single pass. Choosing the right deck size is crucial for efficiency and maneuverability.

- Small Lawns (Up to 1 Acre): For smaller lawns, a deck size of 32 to 42 inches is ideal. These mowers are more maneuverable and can easily navigate around obstacles and tight spaces.

- Medium Lawns (1 to 3 Acres): A deck size of 42 to 54 inches is suitable for medium-sized lawns. These mowers provide a good balance of coverage and maneuverability.

- Large Lawns (3 Acres and Above): For larger properties, consider a deck size of 54 inches or more. Larger decks cover more ground quickly, reducing mowing time but may be less agile in confined areas.

Engine Power

The engine power of a zero turn mower, measured in horsepower (HP), affects its performance, especially on tough terrain and thick grass.

- Low-Power Engines (16-20 HP): Suitable for smaller lawns with flat terrain and lighter grass conditions. These engines are more fuel-efficient and less expensive.

- Medium-Power Engines (20-24 HP): Ideal for medium-sized lawns with moderate slopes and thicker grass. They offer a good balance of power and efficiency.

- High-Power Engines (25 HP and Above): Best for large properties with challenging terrain and dense grass. High-power engines provide the necessary muscle to handle tough mowing conditions effectively.

Transmission Type

The transmission type of a zero turn mower influences its ease of operation and control. Most zero turn mowers come with either hydrostatic or manual transmissions.

- Hydrostatic Transmissions: These offer smooth operation and precise control. They use fluid dynamics to transfer power from the engine to the wheels, allowing for seamless speed adjustments. Hydrostatic transmissions are generally more durable and require less maintenance.

- Manual Transmissions: These are less common in zero turn mowers but can still be found in some models. They are typically more affordable but require manual gear shifting, which can be less convenient than hydrostatic systems.

Additional Features

When choosing a zero turn mower, consider additional features that can enhance your mowing experience and efficiency.

- Comfort Features: Look for mowers with comfortable seats, ergonomic controls, and vibration reduction to make mowing more enjoyable.

- Cutting Technology: Advanced cutting systems, such as mulching kits and bagging options, can provide versatility in handling different grass conditions.

- Durability: Consider mowers with sturdy construction, durable components, and a good warranty to ensure long-term reliability.

Maintaining a zero turn mower involves regular attention to various components to ensure optimal performance and longevity. From draining gas to changing oil, sharpening blades, and winterizing, each step plays a crucial role in keeping your mower in top shape. By following manufacturer guidelines and understanding your specific mower’s needs, you can enjoy efficient lawn care season after season. Proper maintenance not only enhances performance but also extends the lifespan of your mower, providing you with a reliable and effective tool for maintaining a beautiful lawn. Whether you’re choosing a new mower or taking care of an existing one, these insights will help you make informed decisions and achieve the best results in your lawn care efforts.

Advanced Maintenance Tips for Zero Turn Mowers

Maintaining your zero turn mower goes beyond basic upkeep like draining gas and changing the oil. Advanced maintenance practices ensure your mower operates efficiently and extends its lifespan. Here are some detailed advanced maintenance tips:

Fuel System Maintenance

Proper fuel system maintenance is essential for smooth engine operation and to prevent starting issues. Over time, fuel filters and lines can become clogged or deteriorate, affecting performance.

Fuel Filter Replacement:

- Frequency: Replace the fuel filter regularly, typically once a season or after 100 hours of use.

- Procedure: Locate the fuel filter (consult your mower’s manual). Using pliers, disconnect the fuel lines from both ends of the filter. Install the new filter, ensuring the flow direction matches the fuel flow direction indicated on the filter. Reconnect the fuel lines securely.

Fuel Line Inspection:

- Frequency: Inspect fuel lines every few months or before each mowing season.

- Procedure: Visually inspect the fuel lines for any signs of cracks, leaks, or wear. Run your fingers along the lines to feel for any soft spots or signs of deterioration. Replace any damaged fuel lines to prevent leaks and ensure efficient fuel delivery.

Hydraulic System Care

The hydraulic system is vital for the precise maneuverability that zero turn mowers are known for. Proper hydraulic maintenance prevents performance issues and extends the system’s life.

Hydraulic Fluid Check:

- Frequency: Check hydraulic fluid levels before each use or as recommended by the manufacturer.

- Procedure: Locate the hydraulic fluid reservoir. Clean the area around the cap to prevent contamination. Remove the cap and check the fluid level against the dipstick or fill line. Top up with the manufacturer-recommended hydraulic fluid if necessary.

Hydraulic Filter Replacement:

- Frequency: Replace the hydraulic filter as recommended by the manufacturer, typically every 200 hours of operation.

- Procedure: Locate the hydraulic filter (consult your manual). Place a drain pan underneath, then use a filter wrench to remove the old filter. Lubricate the gasket of the new filter with a bit of hydraulic fluid before installing it. Tighten the new filter by hand, then check for leaks after starting the mower.

Cooling System Maintenance

Proper cooling system maintenance is crucial to prevent engine overheating, which can lead to severe damage.

Clean Cooling Fins:

- Frequency: Clean the cooling fins every 25 hours of use or more frequently if operating in dusty conditions.

- Procedure: Locate the cooling fins on your air-cooled engine. Use compressed air or a soft brush to remove debris, dirt, and grass clippings. Ensure the fins are clear to allow proper airflow.

Check Radiator (if applicable):

- Frequency: Check the radiator of liquid-cooled engines every 50 hours of use.

- Procedure: Inspect the radiator for leaks and ensure it’s free from debris and grass clippings. Check the coolant level and top up if necessary with the recommended coolant. Inspect the hoses for any signs of wear or leaks.

Electrical System Checks

A reliable electrical system is essential for starting and operating your mower. Regular checks can prevent unexpected issues.

Inspect Wiring:

- Frequency: Inspect wiring harnesses every few months or at the start of the mowing season.

- Procedure: Look for signs of wear, rodent damage, or loose connections. Ensure all wiring is secured away from moving parts. Use electrical tape or zip ties to secure any loose wires.

Battery Maintenance:

- Frequency: Check the battery monthly, especially during the off-season.

- Procedure: Clean the battery terminals with a mixture of baking soda and water to remove any corrosion. Ensure the connections are tight. Check the battery’s voltage with a multimeter; if it’s below the manufacturer’s recommended level, recharge it. Replace the battery if it no longer holds a charge.

Deck Maintenance

The cutting deck is essential for achieving a clean, even cut. Regular maintenance keeps it in optimal condition.

Deck Cleaning:

- Frequency: Clean the deck after each use.

- Procedure: Use a garden hose to wash away grass clippings and debris. For stubborn buildup, use a plastic scraper. Avoid using excessive water pressure, which can damage components.

Deck Leveling:

- Frequency: Check and adjust the deck for levelness at the start of each mowing season or if you notice uneven cutting.

- Procedure: Park the mower on a flat surface. Measure the distance from the blade tip to the ground on each side of the deck. Adjust the deck height adjusters to ensure the deck is level from side to side and front to back. Consult the operator’s manual for specific adjustment instructions.

By following these advanced maintenance tips, you can ensure your zero turn mower remains in top condition, providing reliable performance and extending its lifespan. Regular, thorough maintenance not only enhances the efficiency of your mower but also helps you avoid costly repairs and downtime.

Operating Tips for Zero Turn Mowers

Operating a zero turn mower efficiently requires skill and proper technique. These tips will help you maximize performance, achieve a clean cut, and prolong the life of your mower:

Practice Maneuvering

Zero turn mowers are known for their agility and ability to turn on a dime. However, they can be challenging to operate smoothly, especially for beginners. Practice these maneuvers in an open area before tackling your lawn:

- Open Area Practice: Find a large, obstacle-free area to practice using the mower’s controls. Familiarize yourself with how each lever or joystick affects the mower’s movement.

- Turning Techniques: Experiment with the mower’s zero turn capabilities. Practice making sharp turns and reversing direction without leaving uncut grass patches.

- Obstacle Navigation: Learn how to navigate around trees, flower beds, and other obstacles without damaging them or the mower.

Maintain Consistent Speed

Maintaining a consistent speed while mowing is crucial for achieving a clean, even cut and avoiding turf damage:

- Smooth Acceleration: Avoid abrupt starts and stops, which can cause scalping or turf tearing.

- Control Levers Smoothly: Gradually increase or decrease speed using the control levers or joystick. Practice gentle movements to maintain control and precision.

- Match Speed to Terrain: Adjust your speed based on the terrain and grass conditions. Slow down on uneven or sloped areas to maintain stability and avoid accidents.

Overlap Mowing Paths

To ensure all grass is cut evenly and avoid leaving uncut strips, overlap your mowing paths slightly:

- Overlap Technique: Each pass with the mower should overlap the previous pass by a few inches. This ensures no patches of grass are missed between mowing rows.

- Maintain a Pattern: Choose a mowing pattern (straight lines or alternating directions) and stick to it. Consistent overlapping ensures a uniform appearance across your lawn.

Avoid Mowing Wet Grass

Mowing wet grass can lead to clumping, uneven cutting, and strain on the mower’s engine. Wait until the grass is dry before mowing:

- Grass Condition: Wet grass sticks together and can clog the mower deck’s discharge chute. This results in uneven discharge and clumping of clippings.

- Prevent Turf Damage: Mowing wet grass can also compact the soil and damage the grass blades, leading to an unhealthy lawn.

- Optimal Mowing Conditions: Schedule mowing during dry periods or in the early morning when dew has dried off the grass. This ensures the mower operates efficiently and maintains lawn health.

Operating a zero turn mower effectively requires practice, patience, and attention to detail. By mastering maneuvering techniques, maintaining consistent speed, overlapping mowing paths, and avoiding mowing wet grass, you’ll achieve professional-quality results with minimal effort. These tips not only enhance mowing efficiency but also contribute to the longevity of your mower and the health of your lawn. Incorporate these practices into your mowing routine to enjoy a well-maintained lawn year-round.

Environmental Considerations for Zero Turn Mowers

Zero turn mowers offer efficient lawn care solutions, but they also have environmental implications that should be considered. Here are key factors to keep in mind:

Emissions and Fuel Efficiency

Modern advancements in engine technology have improved the fuel efficiency and reduced emissions of zero turn mowers compared to older models. Here’s how you can minimize your environmental impact:

- Fuel Efficiency: Choose a zero turn mower with a fuel-efficient engine. Look for models that comply with EPA emissions standards and are certified as environmentally friendly.

- Regular Maintenance: Keep your mower well-maintained. Regularly change oil, replace air filters, and ensure the fuel system is clean. A well-maintained mower operates more efficiently, reducing fuel consumption and emissions.

- Alternative Fuels: Some zero turn mowers are compatible with alternative fuels like propane or electric power. These options can further reduce emissions and dependence on fossil fuels.

Noise Levels

Zero turn mowers can be loud, especially when operating at full throttle or in residential areas. Consider these tips to mitigate noise pollution:

- Ear Protection: Wear ear protection such as earmuffs or earplugs while operating the mower, especially during prolonged use. This protects your hearing from the high decibel levels emitted by the mower engine.

- Time of Operation: Be mindful of the time of day you mow your lawn, especially in residential neighborhoods. Avoid early morning or late evening hours when noise may disturb neighbors.

- Maintenance Practices: Proper maintenance, including keeping blades sharp and decks clean, can reduce mower noise by ensuring smooth operation without unnecessary vibrations or rattling.

While zero turn mowers offer efficiency and precision in lawn care, they also impact the environment through emissions and noise levels. Choosing a fuel-efficient model, maintaining your mower regularly, and using appropriate safety measures can minimize these impacts. By being mindful of environmental considerations, you can enjoy the benefits of a well-maintained lawn while minimizing your carbon footprint and noise disturbance in your community.

Choosing the Right Zero Turn Mower

Selecting the ideal zero turn mower involves careful consideration of your specific lawn care needs and long-term investment goals. Here are key factors to keep in mind:

Consider Your Needs

Lawn Size: Determine the size of your lawn to choose an appropriate deck size and horsepower rating. Larger decks (typically 42 inches or more) cover more ground quickly, but may be less maneuverable in tight spaces compared to smaller decks (32-42 inches).

Terrain: Assess the terrain of your lawn. If you have slopes or uneven ground, opt for a mower with sufficient horsepower and stability to handle these conditions safely.

Features: Evaluate additional features based on your specific requirements:

- Suspension Systems: Provide a smoother ride and reduce operator fatigue, ideal for larger properties.

- Deck Adjustments: Look for easy-to-use height adjustments for varying grass lengths and seasonal conditions.

- Attachments: Consider optional attachments such as baggers, mulchers, or snow plows depending on your year-round lawn care needs.

Budget and Long-Term Investment

Value for Money: Balance the initial cost of the mower with its long-term durability and performance. A higher initial investment in a quality mower from a reputable brand can often pay off in terms of reliability, efficiency, and reduced maintenance costs over time.

Brand Reputation: Choose a brand known for quality craftsmanship and excellent customer support. Research customer reviews and warranty options to ensure you receive reliable service and support throughout the mower’s lifespan.

Zero turn mowers represent a significant advancement in lawn care technology, offering unmatched efficiency, precision, and operator comfort compared to traditional riding mowers. By carefully assessing your lawn size, terrain, desired features, and budget considerations, you can select a zero turn mower that meets your specific needs and delivers superior performance. Whether you’re a homeowner maintaining your own lawn or a professional landscaper servicing multiple properties, choosing the right zero turn mower ensures you achieve a well-manicured and healthy lawn with minimal effort and maximum satisfaction.

Frequently Asked Questions about Zero Turn Mowers

What is a zero turn mower, and how does it differ from a traditional riding mower?

- Zero Turn Mower: A zero turn mower is a type of riding mower with a turning radius that effectively allows it to turn within its own footprint, or “zero turn.” This maneuverability is achieved by independent wheel motors that control each wheel separately.

- Difference: Traditional riding mowers typically have a larger turning radius and steer from the front wheels, requiring wider turns and more maneuvering space.

What are the advantages of using a zero turn mower?

- Speed and Efficiency: Zero turn mowers are faster and more efficient at mowing large areas due to their ability to turn quickly and navigate obstacles with ease.

- Precision Cutting: They provide precise cutting capabilities, reducing the need for trimming and ensuring an even, professional-looking lawn.

- Maneuverability: Excellent maneuverability makes them ideal for navigating around trees, flower beds, and other obstacles without leaving uncut patches.

What size deck should I choose for my zero turn mower?

- Considerations: Deck size should be chosen based on the size of your lawn and the terrain. Larger decks (50 inches or more) are suitable for large, open spaces, while smaller decks (42-48 inches) are more maneuverable in tighter areas with obstacles.

How often should I sharpen the blades on my zero turn mower?

- Frequency: Blades should be sharpened at least once per mowing season or more frequently if you notice a decrease in cutting efficiency. Sharp blades ensure a clean cut, promoting lawn health and reducing stress on the mower’s engine.

What maintenance tasks are crucial for keeping a zero turn mower in good condition?

- Key Maintenance Tasks: Regular maintenance tasks include:

- Changing engine oil and filters.

- Checking and maintaining tire pressure.

- Inspecting and replacing air filters as needed.

- Greasing and lubricating moving parts.

- Checking and adjusting belts and pulleys.

- Cleaning the mower deck and removing debris.

How do I winterize my zero turn mower?

- Steps for Winterization:

- Drain or stabilize the fuel to prevent fuel system issues.

- Change the engine oil and filter to remove contaminants.

- Clean the mower thoroughly to prevent rust and corrosion.

- Store the mower in a dry, sheltered area to protect it from the elements.

What should I do if my zero turn mower won’t start?

- Troubleshooting Steps:

- Check the fuel level and quality. Stale fuel can prevent the engine from starting.

- Inspect the spark plug for fouling or wear and replace if necessary.

- Ensure safety switches (seat switch, blade engagement switch) are engaged properly.

- Check the battery charge and connections, cleaning terminals if necessary.

- Refer to the operator’s manual for specific troubleshooting tips related to your mower model.

Can zero turn mowers be used on hills or slopes?

- Slope Capability: Zero turn mowers are best suited for flat to gently sloping terrain. Use caution when operating on slopes exceeding the manufacturer’s recommended slope limit to prevent tipping or loss of control.

Are zero turn mowers suitable for residential use?

- Residential Use: Yes, zero turn mowers are increasingly popular for residential use due to their efficiency, maneuverability, and professional-quality results. They are particularly beneficial for homeowners with larger lawns or those seeking a time-saving solution for lawn care.

What safety precautions should I follow when operating a zero turn mower?

- Safety Tips:

- Always wear appropriate personal protective equipment (PPE), including eye protection, hearing protection, and sturdy footwear.

- Familiarize yourself with the mower’s controls and safety features outlined in the operator’s manual.

- Avoid mowing in reverse unless absolutely necessary, and use caution when maneuvering around obstacles.

- Keep children, pets, and bystanders at a safe distance while operating the mower.

Source : 1.USDA Plant Hardiness Zone Map

3. National Agricultural Library (NAL)

Final Thought

Zero turn mowers represent a significant advancement in lawn care technology, offering unparalleled speed, maneuverability, and precision for both residential and commercial users. As we’ve explored in this extensive guide, these mowers excel in efficiency, delivering professional-quality results with reduced mowing time and increased productivity.

Key Benefits Recap:

- Efficiency and Speed: Zero turn mowers allow operators to mow faster due to their ability to turn within their own footprint. This saves time and energy, especially on large properties.

- Precision Cutting: The precise maneuverability of zero turn mowers ensures an even, clean cut, reducing the need for additional trimming and promoting a healthier lawn.

- Maneuverability: Their ability to navigate tight spaces, around obstacles, and along borders makes zero turn mowers ideal for complex landscapes and residential properties with intricate landscaping.

- Operator Comfort: Many models offer ergonomic features such as adjustable seats, controls, and suspension systems, reducing operator fatigue during extended mowing sessions.

Maintenance and Care:

Proper maintenance is crucial to ensure your zero turn mower operates reliably and efficiently throughout its lifespan. Regular tasks such as changing oil, sharpening blades, inspecting belts and pulleys, and cleaning the mower deck help prevent breakdowns and extend the mower’s durability. Winterizing the mower before storage protects it from cold weather damage, ensuring it’s ready for use when the mowing season resumes.

Operational Best Practices:

Understanding and practicing safe operation, including reading the operator’s manual, wearing appropriate safety gear, and avoiding aggressive maneuvers on slopes or uneven terrain, ensures both operator safety and optimal mower performance. Adhering to recommended mowing patterns and adjusting settings based on grass type and conditions further enhances efficiency and maintains lawn health.

Environmental Considerations:

Modern zero turn mowers are designed with fuel efficiency and reduced emissions in mind, contributing to environmental sustainability. Choosing models with EFI technology, implementing eco-friendly lawn care practices such as mulching, and minimizing noise pollution are steps towards responsible use of these machines.

In conclusion, whether you’re a homeowner maintaining your personal lawn or a professional landscaper servicing multiple properties, investing in a zero turn mower can significantly enhance your lawn care routine. By following the guidelines and tips outlined in this guide, you can maximize the benefits of your zero turn mower, achieve outstanding results, and ensure long-term satisfaction with your investment.

If you have any more questions or need further assistance regarding zero turn mowers or any other lawn care topics, feel free to reach out. Happy mowing!

Leave a Reply